What is the reason that cause the stainelss steel hydraulic hose noise during working?

Under actual working situation, many customers reflect that, the metal hydraulic hoses may cause some noise which may lead to some bad influence, actually, there are many reasons that cause metal hose flexible noise, mainly includes, high fluid density, friction of fluid in the pipe and vibration of the pipe wall. It also relates to the corrugated structure of hydraulic hoses, the bumpy boundary layer creates significant coupling with the liquid, further aggravating vibrations. The annular structure of the inner tube of metal braided hydraulic hose, makes the noise can not go through the tube straightly.

How to deal with the problem of working noise of hydraulic hose assemblies?

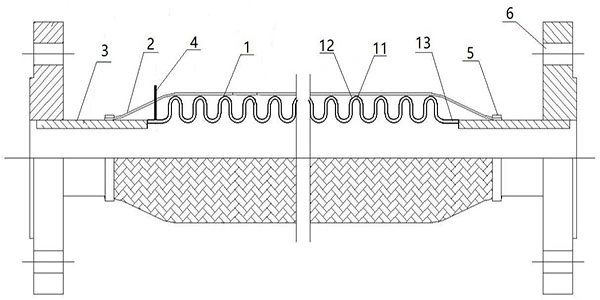

Regarding this issue of high pressure metal hose noise during working, we usually takes the solution of add an additional noise reduction layer apart from the inner corrugated hose layer. The mainly function of the noise reduction layer is to makes the two layers form a empty space, this empty space layer can reach function of reducing the transmission of noise in the air, thus to reach the purpose of reducing high pressure flexible hose noise during working.

After adding reduction layer, the metal flex hose flexibility will be get weak, but it also will be a good solution for customers if they do not have high requirement towards high pressure stainless steel braided hose flexibility.

Please take below picture as reference of the stripwound metal hose with noise reduction layer:

There are also customers asking if noise be reduced with PTFE inner structure?

About the PTFE lined metal hose, there are 2 different kinds of inner PTFE tube, which are separately corrugated structure and smooth structure. The corrugated is the main reason which cause metal hydraulic hoses working noise, so we take smooth surface PTFE tube as the noise reduction solution. And experience fact is that, smooth surface PTFE tube really can reduce working noise. But PTFE smooth inner tube, do not have good flexibility character, besides, stainless steel braided PTFE hose is with very expensive price, so actually, we do not recommend this approach.