Metal Hose Brief Introduction

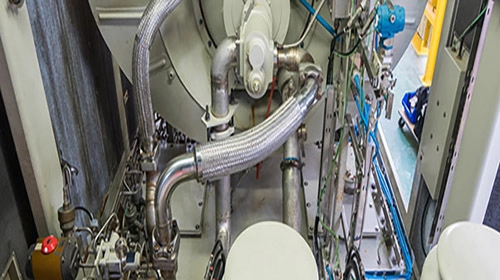

Metal hose is an important component in modern industry pipeline connection system, and it has the advantage towards rubber hose of high temperature resistance, low temperature resistance and corrosion resistance. Metal hose has super flexibility performance the same as rubber hose with its special wove structure, and also perform with excellent extreme temperature and decay resistance ability, also along with the performance anti-aging. Metal hose is widely used among industry of machinery, chemical, oil and gas, metallurgical and food.

Metal Hose Function

During complex pipeline system, there is always many kinds of difficulties towards installation due to the restriction of spatial position, and it is also easy lead to local cold correction inevitably for various reasons, such kind of cold correction has large vary change range low form a few millimeters to tens of millimeters, even can be high to hundreds millimeters, according to evidence, the pipeline system pressure grows along with this data become large. These installation pressure left in the pipeline system will be the most dangers factors of safety. So the application of metal hose brings convenience to pipeline system installation due to its excellent flexibility ability, and it also plays important insurance function to the pipeline system safety.

In modern industrial fields, there always exists many negative factors such as fatigue, corrosion, vibration, compression, shock apart from pressure and temperature, under such situation, it is most suitable for metal hose to compensate the pipeline system position. Although rubber hose has good flexibility, it weaks in pressure, temperature resistance and anti-aging fields, rubber hose always out of work after several months service time, thus excellent performance of metal hose is completely come out.

Metal hose can absorb the shock produced by the unit as well as the noisy generated by fluid pulsation in pipeline system, that is the reason why many pipeline system takes metal hose as the final solution.

Structure

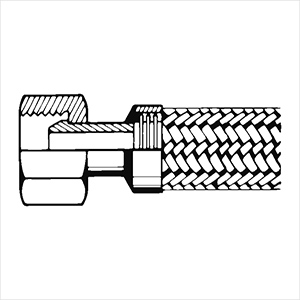

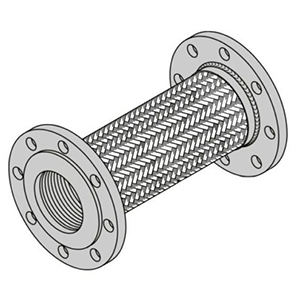

Metal hose consists of three parts: inner corrugated metal tube, outer metal mesh and fitting connection. Inner part corrugated metal tube is the main body of metal hose, it plays the role of keeping hose flexibility character, outer metal mesh mainly bear the function of pressure-bearing, and fitting connector serves as a connection, different fitting connection is selected according to various connection requirement.

Pressure Bearing

Pressure bearing ability of metal hose always change from 18 bar to 120 bar. Metal hose is the mainly pressure bearing component that installed within pipeline transfer system, different braid layers such as 1 layer braid, 2 layer braid or multi-layer braid can be selected according to different pressure rating requirement or application scene.

Advantage

Metal hose always takes raw material of austenitic stainless steel, therefore, it ensures the excellent high and low temperature resistance and corrosion resistance performance, it also has broad application range from low -196℃ up to 450℃, the stainless steel application grade is selected according to transfer medium corrosion situation of the metal hose.

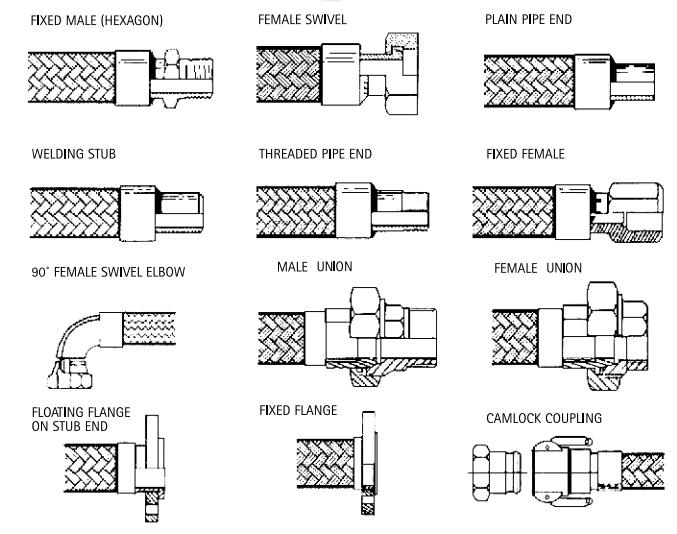

Fitting Connection of Metal Hose

The function of fitting connection is to joint metal mesh and inner corrugated metal tube, at the mean time, fitting connection is also the medium for connecting other metal hose fitting. Material of the fitting connection is always the same as corrugated metal tube and metal mesh, most of them takes stainless steel as raw material. To reduce cost, many big size metal hose often takes carbon steel material to produce fitting connection under situation of transferring low extent corrosion medium . The sealing form of fitting connection always to be thread type, flange type and quick release type:

|

Part No. |

Size |

Braid Layer |

Max Working Pressure |

Test Pressure |

Bend Radius |

Weight | ||||||

| inch | mm | psi | mpa | bar | psi | mpa | bar | static | dynamic | kg/mtr | ||

| QTMH-01 | 1/4” | 6 | 1 | 1740 | 12 | 120 | 3480 | 24 | 240 | 40 | 100 | 0.2 |

| 2 | 2610 | 18 | 180 | 5220 | 36 | 360 | 75 |

150 |

0.4 | |||

|

QTMH-02 |

3/8” |

10 |

1 | 1522 | 10.5 | 105 | 3044 | 21 | 210 | 75 | 150 | 0.3 |

| 2 | 2320 | 16 | 160 | 4640 | 32 | 320 | 100 | 200 | 0.5 | |||

|

QTMH-03 |

1/2“ |

12 |

1 | 1160 | 8 | 80 | 2320 | 16 | 160 | 90 | 170 | 0.4 |

| 2 | 1740 | 12 | 120 | 3480 | 24 | 240 | 150 | 200 | 0.6 | |||

|

QTMH-04 |

5/8” |

16 |

1 | 1015 | 7 | 70 | 2030 | 14 | 140 | 120 | 250 | 0.5 |

| 2 | 1595 | 11 | 110 | 3190 | 22 | 220 | 180 | 280 | 0.7 | |||

|

QTMH-05 |

3/4“ |

20 |

1 | 942 | 6.5 | 65 | 1884 | 13 | 130 | 150 | 220 | 0.6 |

| 2 | 1377 | 9.5 | 95 | 2754 | 19 | 190 | 200 | 300 | 0.8 | |||

|

QTMH-06 |

1" |

25 |

1 | 942 | 6.5 | 65 | 1884 | 13 | 130 | 170 | 250 | 0.8 |

| 2 | 1160 | 8 | 80 | 2320 | 16 | 160 | 220 | 350 | 1 | |||

|

QTMH-07 |

1-1/4" |

32 |

1 | 725 | 5 | 50 | 1450 | 10 | 100 | 200 | 270 | 1.2 |

| 2 | 1015 | 7 | 70 | 2030 | 14 | 140 | 250 | 400 | 1.4 | |||

|

QTMH-08 |

1-1/2" |

40 |

1 | 580 | 4 | 40 | 1160 | 8 | 80 | 220 | 400 | 1.5 |

| 2 | 1015 | 7 | 70 | 2030 | 14 | 140 | 270 | 430 | 1.7 | |||

|

QTMH-09 |

2" |

50 |

1 | 507 | 3.5 | 35 | 1014 | 7 | 70 | 250 | 430 | 1.8 |

| 2 | 725 | 5 | 50 | 1450 | 10 | 100 | 280 | 460 | 2 | |||

|

QTMH-10 |

2-1/2‘ |

65 |

1 | 507 | 3.5 | 35 | 1014 | 7 | 70 | 280 | 450 | 3 |

| 2 | 580 | 4 | 40 | 1160 | 8 | 80 | 300 | 500 | 5 | |||

|

QTMH-11 |

3” |

80 |

1 | 290 | 2 | 20 | 580 | 4 | 40 | 320 | 480 | 4 |

| 2 | 435 | 3 | 30 | 870 | 6 | 60 | 360 | 520 | 6 | |||

|

QTMH-12 |

4“ |

100 |

1 | 333 | 2.3 | 23 | 666 | 4.6 | 46 | 350 | 520 | 5 |

| 2 | 435 | 3 | 30 | 870 | 6 | 60 | 400 | 560 | 7 | |||

|

QTMH-13 |

6" |

150 |

1 | 290 | 2 | 20 | 580 | 4 | 40 | 400 | 550 | 8 |

| 2 | 362 | 2.5 | 25 | 724 | 5 | 50 | 430 | 600 | 10 | |||

|

QTMH-14 |

8" |

200 |

1 | 217 | 1.5 | 15 | 434 | 3 | 30 | 430 |

600 |

12 |

| 2 | 261 | 1.8 | 18 | 522 | 3.6 | 36 | 460 | 650 | 14 | |||