Composite Hose Brief Introduction

Composite hose is a kind of multi-layer thermoplastic hose, inner layer composed of PP and PTFE material, with inner and outer spiral stainless steel wire. It is widely used in oil and chemical industrial area as well as hazardous chemicals field, such as liquid and gas which is of danger, inflammable, corrosive and environmentally polluting character. Composite hose can satisfy all the transfer requirement, no matter it is corrosive sulfuric acid, nitric acid, hydrofluoric acid flammable explosive solvent products or high and low temperature products.

Composite Hose Advantage

Composite hose has all the advantage of metal hose and plastic hose, that is, good barrier property, corrosion resistance, resistance to breakage, as well as low cost and beautiful appearance, all these leads to its popular during all industrial application area.

Composite Hose Character

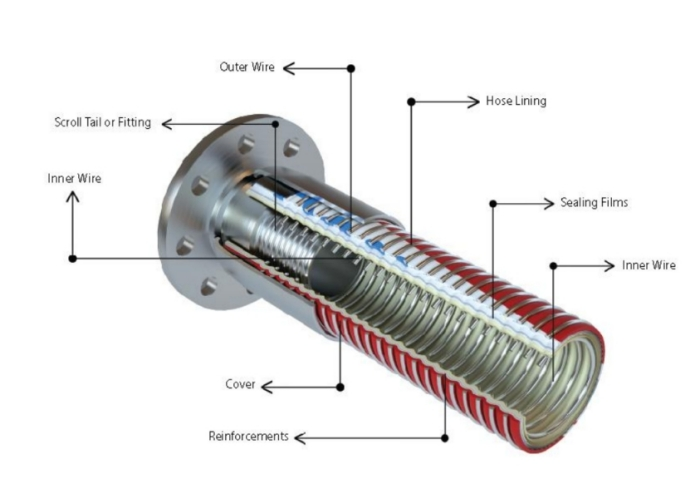

Composite Hose Structure

Inner Wire:usually use stainless steel wire, galvanized steel wire, aluminium alloy wire, and PP or Teflon clad steel wire

Outer Wire: always use stainless steel wire or galvanized steel wire

Inner Layer: Teflon/ Polietilene/ Nylon/PET/PP (different material will be selected according to detailed transfer medium)

Composite Hose Classification

With quick development speed of composite hose in industrial field, there appears many kinds of composite hose, totally it can be sorted as 7 categories:

1. Oil Resistance Composite Hose: oil resistance composite hose is widely used in many kinds of oil liquids products transfer, include gasoline, diesel, kerosene, crude oil, etc.

2. Chemical Composite Hose: chemical hose is used to transfer corrosive chemical liquids and gas, it really shows strong chemical corrosion resistance performance.

3. Car Application Composite Hose: car application composite hose is specialized applied with tank car, it has the character of good flexibility, mainly suitable for frequently bending moving application area.

4. Ship Loading and Unloading Composite Hose: this kind composite hose is mainly used with shipping coat in the dock.

5. Paint and Coating Delivery Composite Hose: it is designed to transfer paint and coating products, paint and coating delivery composite hose has the advantage of solvent resistance, wear resistance and excellent anti-oxidation performance.

6. Low Temperature Resistance Composite Hose: low temperature composite hose is used to transfer low temperature liquid or medium in low temperature environment, such as LDPE, LPG,LNG and dry ice.

7. High Temperature Composite Hose:it used to transfer high temperature fluid, such as hot water, hot oil.

| Size |

Max Working Pressure |

Test Pressure |

Bend Radius | Weight | |||||

| inch | mm | psi | mpa | bar | psi | mpa | bar | mm | kg/mtr |

| 1“ | 25 | 350 | 2.5 | 25 | 525 | 3.6 | 36 | 65 | 0.8 |

| 1-1/2" | 38 | 350 | 2.5 | 25 | 525 | 3.6 | 36 | 100 | 1.3 |

| 2” | 50 | 350 | 2.5 | 25 | 525 | 3.6 | 36 | 180 | 1.8 |

| 2-1/2" | 65 | 350 | 2.5 | 25 | 525 | 3.6 | 36 | 220 | 2.5 |

| 3“ | 76 | 350 | 2.5 | 25 | 525 | 3.6 | 36 | 280 | 3 |

| 4" | 102 | 320 | 2.2 | 22 | 480 | 3.3 | 33 | 400 | 5 |

| 6” | 150 | 320 | 2.2 | 22 | 480 | 3.3 | 33 | 550 | 12 |

| 8" | 200 | 320 | 2.2 | 22 | 480 | 3.3 | 33 | 800 | 15 |

| 10“ | 250 | 320 | 2.2 | 22 | 480 | 3.3 | 33 | 1000 | 20 |